| Since 1970 Ross Industries has revolutionized meat tenderizing more effectively and efficiently than anything currently in the industry. Since its humble beginnings in a garage in northern Virginia Ross has invented and incorporated technologies that were far ahead of the industry. For the first time meat processors and retailers were able to tenderize primal sections and cuts without having to remove the bone. | The Ross Tenderizer literally created new markets by allowing processors to break the age-old "cattle cycle" and tenderize the tougher, less expensive cuts of range-fed cattle to obtain the higher quality and prices of grain-fed beef. |

Ross Table Top Macerator (Cuber) C770T & Ross C770T Table Top Cuber

Finally, a table top cube steak machine has been made with durability and operator safety in mind! Reliable and

durable "Operator Friendly" portable cube steak appliance.

Model

C770T

Machine Dimensions

19.75”L x 24.50”W x 18”H - 50cm x 62cm x 46cm

Voltage Requirements

115VAC / 60Hz – 9A

Machine Weight

145 lbs. - (66 kg)

Certification

CE Compliant

Blade Speed

109 RPM

Chute Width

8” - (203 mm)

Product Temperature

32°F to 40°F (0° to 4.4°C)

Create tender cube steaks quickly, safely, and reliably.

Patent Pending Safety Feature

Quick release cartridge drive mechanism disengages and instantaneously stops upon safety cover removal!

Key Features

- Industrial safety control

- Lockable safety cover

- Uni-body stainless steel construction

- Cartridge style cube rollers easily removed

for sanitation - Alternate cartridge designs available

- Removable cartridges, no tools required.

Various Head Configurations are Available

Standard unit comes with a cube steak blade and spacer set up. A strip cutting head is under development. Inform us of your specific application and we can deliver a head that meets your requirements.

Applications

- Cube Steak

- Chicken Fried Steak

- Schnitzel

- Stir Fry

- And More

Machine Dimensions

19.75”L x 24.50”W x 18”H - 50cm x 62cm x 46cm

Voltage Requirements

115VAC / 60Hz – 9A

Machine Weight

145 lbs. - (66 kg)

Certification

CE Compliant

Blade Speed

109 RPM

Chute

Width 8” - (203 mm)

Product Temperature

32°F to 40°F (0° to 4.4°C

Ross C770 and C770N Tendercube

Incorporating Ross Tenderizing Technology, the Ross Tendercube produces Cube Steak through a four-step process:

- Initial Crosscut: Product thickness is reduced while crosscutting the product.

- Mechanically Tenderize: Product is tenderized and flattened simultaneously

using Ross Tenderizing Technique. - Flatten: Assures desired product thickness is attained.

- Final Crosscut: Product is crosscut ensuring tenderness result is achieved.

Processor Benefits

- Meet desired Tenderness level and upgrade

leaner cuts. - Yield Uniform product thickness.

- One machine, one pass =

maximum

plant productivity and efficiency!

Key Features

- Main conveyor belt: speed can be adjusted

to vary tenderness levels.

- Flattening plate: adjustable to control

product thickness. - Cartridge design: cube roller and tenderizer

head assemblies are easily removed without tools,

for ease of cleaning. - Includes: Washdown cart, for cube roller

assemblies, tenderizing heads and flattening

plate during cleaning.

Ross Tenderizer TC700M

Tenderizing makes the less-than-tender cuts eat with the palatability scores of the top-graded middle meats, selling more rounds and increasing volume. Because they're tenderized, rounds can be cut thicker (up to 3/4") making each package more profitable.

Consumers see another value in tender meat: healthier meals. Natural fat content of most rounds is about 5%, compared with 18 - 22% for middle meats. Leaner round cuts that eat as tender as prime - while representing a quarter of the fat content - are a true value to the consumer.

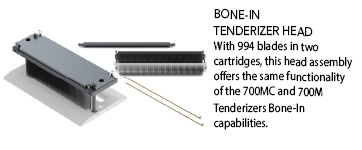

Ross Tenderizers dramatically improve the mouth-feel of any cut of meat by making 32 unique T-shaped surgical incisions per square inch in bone-in and boneless products.

Key Features

- The standard of the industry for 30 years with thousands of installations.

- Sinew, connective tissue and muscle fiber are severed, resulting in truly tender portions.

- Cooking time is reduced.

- Moisture is retained, enhancing flavor.

- Magnetic head design positions tenderizing blades in magnetic carriers that retract when

encountering bones or frozen meat. - Hi/Lo product height adjustment allows operator to adjust tenderizer head clearance for

tenderizing all primals, bone-in or boneless. - Two models are available with nominal rates of 3,000 or 5,000 lbs per hour.

Specifications

Model TC700M

Machine Dimensions

72" (L) x 24" (W) x 40" (H)

Approval/Certification

USDA (CE Compliant Model Available

Voltage Requirements

200 - 575V, 50/60 Hz, 17-6.5A

Nominal Production Rate

5,000 lbs/hr

Conveyor Speed

5.5 ft/min

Maximum Product Height

LO Position = 7"" / HI Position = 9""

Conveyor Width

12"

Product Temperature(s)

32 - 40 F (0-5C)

Model TC700MC

Machine Dimensions

52" (L) x 24" (W) x 40" (H)

Approval/Certification

USDA

Voltage Requirements

200-575V, 50/60 Hz, 7-3.3A

Nominal Production Rate

3,000 lbs/hr

Conveyor Speed

3.3 ft/min

Maximum Product Height

LO Position = 7"" / HI Position = 9""

Conveyor Width

12"

Product Temperature(s)

32 - 40 F (0-5 C)

Ross Tenderizer Model TC700W

Since 1968, Ross Tenderizers have enabled processors to produce and upgrade meat cuts with guaranteed tenderization. Stainless steel blades produce incisions in boneless meat products to sever sinew, connective tissue, and muscle fiber.

Processor Benefits

- Aging time is reduced, decreasing purge.

- Cooking time is reduced.

- Moisture is retained to enhance flavor.

Key Features

- New boneless-only tenderizing head.

- Sanitary liquid recovery.

- High production volume (Nominal rate of

10,000 lbs per hour).

- Adjustable conveyor advance.

- Variable stroke rate.

- Wash-down cart for storing removable

parts during cleaning.

Product Applications

Beef

Poultry

Pork

Lamb

Seafood

Ross Guarantees Tenderness! Increase productivity and profits with the Boneless Tenderizer.

Machine Dimensions

110”L x 45”W x 68”H - 2794mm x 1143mm x 1727mm

Machine Weight

2,400 lbs - (1090 kg)

Voltage Requirements

200-460V – 50/60Hz – 32-14A

Nominal Production Rate

10,000 lbs/hr - (4,500 kg/hr)

Conveyor Advance Rate

0.7”/stroke (1.8cm) - 1.0”/stroke (2.5cm) - 2.3”/stroke

(5.9cm)

Variable Stroke Rate

60 / 70 / 80 strokes/minute

Maximum Product Height

7” (17.7 cm)

Conveyor Width

28” (711 mm)

Product Temperature

32°F to 40°F (0° to 5°C)