| INDEX |

| SAWS (9) |

| GRINDERS (14) |

| SLICERS (7) |

| VACUUM TUMBLERS (7) |

| CUTTERS CHIPPERS, PRO SERIES, FOOD FORMERS |

Carl G. Biro, Sr. was an American immigrant who founded the seedling company of BIRO Manufacturing in the early 1920's. Carl had a humble beginning as the son of a local blacksmith in his native country of Hungary. After settling in America, Carl became an apprentice who attended technical school at night and on the weekends Eventually, Carl became the proprietor of his own meat market. During his proprietorship, he realized the need for a practical machine which would cut meat more effectively. Thus, in 1921, unable to ignore his ambitions of creating a practical meat cutter, Carl decided to dispose of his meat market so that he could devote more time to his concept. He leased an old church and used the equipment which was available and affordable at the time to pursue his "American Dream" and produce the first BIRO Power Meat, Fish and Bone Cutter. In time, Carl's machine gained national as well as international recognition and acceptance. Biro's leadership in the meat cutting industry was unmistakably established. In order to keep up with the growing product demand, BIRO Manufacturing moved from the leased church building to a small but modern factory building. This establishment has grown to be the facility which now houses our corporate headquarters |

Today, The BIRO Manufacturing Company markets over 35 items, including meat saws, tenderizers, meat grinders, chicken cutters, vacuum tumblers, horizontal slicers, and other meat processing machinery. This equipment is used in the United States and throughout the world. The company has certainly grown tremendously from the tiny seedling factory conceptualized by Carl Biro during the early 20's! Those involved in The BIRO Manufacturing Corporation today strive for progress towards a still more advanced product and to gain a greater measure of goodwill and respect from those who deal with it. We here at BIRO face the future with the firm belief that . .."The best is yet to come." |

Slicers

MODEL B300M GRAVITY FEED MANUAL SLICER

BIRO slicers are designed to provide trouble free service in a WET MEAT ROOM ENVIRONMENT with features such as Waterproof Motor, Electrical Components and Connections plus Non-Corrosive Metals, all of which add to the water resistant benefits of this slicer.

Our B300M has a 12” (300mm) Hollow Ground Alloy Steel blade that allows a slicing capacity to nearly 7-1/2” (190mm) on round products at a thickness from 0 to 9/16” (0-14mm) slice.

Index knob has indicator positions showing rotation of one millimeter increments for consistency within multiple slicing stations.

Built In Safety Features – Blade protective ring guard prevents exposed blade edge when the blade cover is removed for cleaning. Product table lockout prevents thickness gauge from being opened during cleaning. Emergency shut-off and thermal overload/no volt release prevents accidental turn on after power outages. Remote sharpener mounts easily when needed but is stored away from the slicer when not in use providing added hygiene security to the slicing operation.

SPECIFICATIONS

MODEL

B300M Gravity Feed Manual Slicer

CONSTRUCTION

BODY – ANODIZED POLISHED ALUMINUM CAST WITH NON-CORROSIVE METAL FRAME

MOTORS

IP 65 – 1/2HP (.35 KW) 115V 60 HZ 1 PH INTERNALLY

COOLED, WATER RESISTANT

IP 65 – 1/2HP (.35 KW) 220V 50 HZ 1 PH INTERNALLY

COOLED, WATER RESISTANT

STANDARD FEATURES

AUTOMATIC SPRING LOADED BELT TENSIONING, POLYGROOVE BELT DRIVE PROVIDES OPTIMUM PERFORMANCE, BLADE PROTECTIVE RING GUARD PREVENTS EXPOSED BLADE EDGE DURING CLEANING, REMOVABLE PRODUCT TABLE FOR EASIER CLEANING (B300M), THERMAL OVERLOAD/NO VOLT RELEASE PREVENTS ACCIDENTAL TURN ON AFTER POWER OUTAGES, GREEN PUSHBUTTON ON-OFF CONTROL AND RED E-STOP BUTTON, WATER RESISTANT IP 65 MOTOR, WIRING HARNESS, ELECTRONIC CONTROLS, & CONNECTORS, DETACHABLE SHARPENER ASSEMBLY – HELPS PROVIDE HYGIENIC SLICING AREA, PRODUCT FENCE – FOR USE ON NARROW PRODUCTS

BLADE

12” (300MM) HOLLOW GROUND ALLOY STEEL

MAX. ROUND CUT 7.5” (190MM)

MAX. RECT. CUT

10” (254MM) X 5.5” (139MM)

CERTIFICATION

NSF, (CE – Call Factory)

WEIGHT

UNCRATED – 72 LBS. (33 KG) CRATED – 101 LBS.

(46 KG)

DIMENSIONS UNCRATED

18”L (456MM) DEPTH FOOT-TO-FOOT SPACE

25-3/4” (654MM) OVERALL 14”W (366MM)

FOOT-TO-FOOT SPACE 22” (560MM)

OVERALL 17-3/4”H (450MM)

DIMENSIONS CRATED

28”L (711MM) x 24”W (609MM) x 23”H (584MM)

Item Number: LIT-B300M/B350M/B350MV-354

MODEL B350A GRAVITY FEED AUTOMATIC SLICER

The BIRO B350A is designed to provide trouble free service in a WET MEAT ROOM ENVIRONMENT. Features such as Water Resistant Motor, Electrical Components and Connections, plus Non-Corrosive Metals, all add to the water protection benefits of the slicer. With THREE AUTOMATIC SPEEDS, the Operator can select the position best suited for the products being sliced or can be used in the MANUAL POSITION for a minimal number of slices to be cut.

• BLADE – 13-3/4″ (350mm) Hollow Ground Alloy Steel has a special (patented) design to relieve surface suction on wet products and will allow a slicing capacity of 9.5″ on round products. The THICKNESS CONTROL allows cuts from 0 to 1″ (25mm) with indicator positions shown on the Index Knob in one millimeter increments allowing precise slice consistency.

• DESIGN – Minimum number of removable parts allow for EASY CLEAN UP while the ergonomic and EASY-GLIDE CARRIAGE allows no resistance during the need for a manual operation. The Automatic operation provides an auto piece count selection from 0-99 pieces with automatic shut-off.

• BUILT-IN SAFETY FEATURES – Blade Protective ring guard prevents exposing the blade’s edge when the blade cover is removed for cleaning. Product table lockouts prevent the thickness gauge from being opened during cleaning. Emergency shut-off and thermal overload/no volt release prevents accidental turn on after power outages. Remote sharpener mounts easily when needed but is stored away from the slicer when not in use, providing added hygiene security to the slicing operation.

SPECIFICATIONS

MODEL

B350A GRAVITY FEED AUTOMATIC SLICER

CONSTRUCTION

BODY – ANODIZED POLISHED ALUMINUM CAST WITH NON-CORROSIVE METAL FRAME

MOTORS

IP 65 – 1/2 HP (.35 KW) 115V 60 HZ -1 INTERNALLY COOLED. (STANDARD U.S.A. VOLTAGE)

IP 65 – 1/2 HP (.35 KW) 220V 60 HZ -1 INTERNALLY COOLED.

IP 65 – 1/2 HP (.35 KW) 220V 50 HZ -1 INTERNALLY COOLED.

STANDARD FEATURES

BLADE – 13-3/4″ (350MM) HOLLOW GROUND ALLOY STEEL – 200 RPM OVERSIZED PRODUCT TABLE 13-1/4″ (337MM) WIDE BY 12-1/2″ (318MM) LONG, MAXIMUM PRODUCT CUT – ROUND 9-1/2″ (241MM), MAXIMUM PRODUCT CUT – RECTANGULAR 11-3/4′ X 6″ (298 X 152MM), MAXIMUM PRODUCT CUT – SQUARE 7-1/4″ X 7-1/4″ (184 X 184MM), AUTOMATIC SPRING LOADED BELT TENSIONING, BLADE PROTECTIVE RING GUARD PREVENTS EXPOSED BLADE EDGE DURING CLEANING, TILT-AWAY PRODUCT TABLE LOCKOUT PREVENTS THICKNESS GAUGE FROM BEING OPENED DURING CLEANING, THERMAL OVERLOAD/NO VOLT RELEASE PREVENTS ACCIDENTAL TURN ON AFTER POWER OUTAGES, GREEN PUSHBUTTON ON/OFF CONTROL AND RED E-STOP BUTTON, POLYGROOVE BELT DRIVE PROVIDING OPTIMUM PERFORMANCE, WATER RESISTANT IP 65 MOTOR, WIRING HARNESS, ELECTRONIC CONTROLS, CONNECTORS, PRODUCT FENCE – FOR USE ON NARROW PRODUCTS

AUTOMATIC SPEED #1

SHORT STROKE 48 PER. MIN., MEDIUM STROKE 40 PER. MIN., LONG STROKE 38 PER. MIN.

AUTOMATIC SPEED #2

SHORT STROKE 56 PER. MIN., MEDIUM STROKE 45 PER. MIN., LONG STROKE 45 PER. MIN.

AUTOMATIC SPEED #3

SHORT STROKE 60 PER. MIN., MEDIUM STROKE 50 PER. MIN., LONG STROKE 50 PER. MIN.

CERTIFICATIONS

NSF, ETL (U.S.), ETLC (Canada), CE (optional)

WEIGHT

UNCRATED – 106 LBS. / 48 KG. CRATED – 121 LBS. / 55 KG.

DIMENSIONS

UNCRATED – OVERALL DEPTH 30-1/2″ (775MM) OVERALL WIDTH 24″ (610MM) OVERALL HEIGHT 35-1/2″ (901MM)

FOOT TO FOOT DEPTH 23-1/4″ (589MM) OUTSIDE WIDTH 17-3/4″ (450MM) OUTSIDE

CRATED – 28″ (711MM) X 32-1/2″ (826MM) X 33-1/2″ (850MM)

OPTIONS

VEGETABLE CHUTE 8-1/4″ (209MM) DIAMETER

BAGEL CHUTE 4-3/4″ (120MM) DIAMETER

Item Number: LIT-B350A-355

MODEL B350M GRAVITY FEED MANUAL SLICER

BIRO slicers are designed to provide trouble free service in a WET MEAT ROOM ENVIRONMENT with features such as Waterproof Motor, Electrical Components and Connections plus Non-Corrosive Metals, all of which add to the water resistant benefits of this slicer.

Our B350M has a 13-3/4” (350mm) Hollow Ground Alloy Steel blade that allows a slicing capacity to nearly 10” (254mm) on round products at a thickness from 0 to 1-1/8” (0-30mm) slice.

Index knob has indicator positions showing rotation of one millimeter increments for consistency within multiple slicing stations.

Built In Safety Features – Blade protective ring guard prevents exposed blade edge when the blade cover is removed for cleaning. Product table lockout prevents thickness gauge from being opened during cleaning. Emergency shut-off and thermal overload/no volt release prevents accidental turn on after power outages. Remote sharpener mounts easily when needed but is stored away from the slicer when not in use providing added hygiene security to the slicing operation.

SPECIFICATIONS

MODEL

B350M GRAVITY FEED MANUAL SLICER

CONSTRUCTION

BODY – ANODIZED POLISHED ALUMINUM CAST WITH NON-CORROSIVE METAL FRAME

MOTORS

IP 65 – 1/2HP (.35 KW) 115V 60 HZ 1 PH INTERNALLY COOLED, WATER RESISTANT

IP 65 – 1/2HP (.35 KW) 220V 50 HZ 1 PH INTERNALLY COOLED, WATER RESISTANT

STANDARD FEATURES

AUTOMATIC SPRING LOADED BELT TENSIONING, POLYGROOVE BELT DRIVE PROVIDES OPTIMUM PERFORMANCE, BLADE PROTECTIVE RING GUARD PREVENTS EXPOSED BLADE EDGE DURING CLEANING, TILT-AWAY PRODUCT TABLE LOCKOUT PREVENTS THICKNESS GAUGE FROM BEING OPENED DURING CLEANING, THERMAL OVERLOAD/NO VOLT RELEASE PREVENTS ACCIDENTAL TURN ON AFTER POWER OUTAGES, GREEN PUSHBUTTON ON-OFF CONTROL AND RED E-STOP BUTTON, WATER RESISTANT IP 65 MOTOR, WIRING HARNESS, ELECTRONIC CONTROLS, & CONNECTORS, DETACHABLE SHARPENER ASSEMBLY – HELPS PROVIDE HYGIENIC SLICING AREA, PRODUCT FENCE – FOR USE ON NARROW PRODUCTS

BLADE

13-3/4” (350MM) HOLLOW GROUND ALLOY STEEL

MAX. ROUND CUT

10” (254 MM)

MAX. RECT. CUT

12-1/2” x 9” (317MM x 228MM)

CERTIFICATION

NSF, ETL (U.S.), ETLC (CANADA), ETL-SANITATION, (CE – CALL FACTORY)

WEIGHT

UNCRATED – 77 LBS. (35 KG)

CRATED – 121 LBS. (55 KG)

DIMENSIONS UNCRATED

22”L (558MM) DEPTH, FOOT-TO-FOOT SPACE 32” (813MM) OVERALL 16”W (406MM) FOOT-TO-FOOT SPACE 27” (685MM) OVERALL 23”H (584MM)

DIMENSIONS CRATED

33”L (838MM) x 28”W (711MM) x 28”H (711MM)

Item Number: LIT-B300M/B350M/B350MV-354

MODEL B350MV HORIZONTAL FEED MANUAL SLICER

BIRO slicers are designed to provide trouble free service in a WET MEAT ROOM ENVIRONMENT with features such as Waterproof Motor, Electrical Components and Connections plus Non-Corrosive Metals, all of which add to the water resistant benefits of this slicer. Our B350MV has a 13-3/4” (350mm) Hollow Ground Alloy Steel blade that allows a slicing capacity to nearly 10-1/2” (266mm) on round products at a thickness from 0 to 13/16” (0-21mm) slice.

Index knob has indicator positions showing rotation of one millimeter increments for consistency within multiple slicing stations.

Built In Safety Features – Blade protective ring guard prevents exposed blade edge when the blade cover is removed for cleaning. Product table lockout prevents thickness gauge from being opened during cleaning. Emergency shut-off and thermal overload/no volt release prevents accidental turn on after power outages. Remote sharpener mounts easily when needed but is stored away from the slicer when not in use providing added hygiene security to the slicing operation.

SPECIFICATIONS

MODEL

B350MV HORIZONTAL FEED MANUAL SLICER

CONSTRUCTION

BODY – ANODIZED POLISHED ALUMINUM CAST WITH NON-CORROSIVE METAL FRAME

MOTORS

IP 65 – 1/2HP (.35 KW) 115V 60 HZ 1 PH INTERNALLY COOLED, WATER RESISTANT

IP 65 – 1/2HP (.35 KW) 220V 50 HZ 1 PH INTERNALLY COOLED, WATER RESISTANT

STANDARD FEATURES

AUTOMATIC SPRING LOADED BELT TENSIONING, POLYGROOVE BELT DRIVE PROVIDES OPTIMUM PERFORMANCE, BLADE PROTECTIVE RING GUARD PREVENTS EXPOSED BLADE EDGE DURING CLEANING, TILT-AWAY PRODUCT TABLE LOCKOUT PREVENTS THICKNESS GAUGE FROM BEING OPENED DURING CLEANING, THERMAL OVERLOAD/NO VOLT RELEASE PREVENTS ACCIDENTAL TURN ON AFTER POWER OUTAGES, GREEN PUSHBUTTON ON-OFF CONTROL AND RED E-STOP BUTTON, WATER RESISTANT IP 65 MOTOR, WIRING HARNESS, ELECTRONIC CONTROLS, & CONNECTORS, DETACHABLE SHARPENER ASSEMBLY – HELPS PROVIDE HYGIENIC SLICING AREA, PRODUCT FENCE – FOR USE ON NARROW PRODUCTS

BLADE

13-3/4” (350MM) HOLLOW GROUND ALLOY STEEL

MAX. ROUND CUT

10-1/2” (266MM)

MAX. RECT. CUT

12” x 10” (304MM x 254MM)

CERTIFICATION

NSF, ETL (U.S.), ETLC (CANADA), ETL-SANITATION, (CE – CALL FACTORY)

WEIGHT

UNCRATED – 77 LBS. (35 KG)

CRATED – 121 LBS. (55 KG)

DIMENSIONS UNCRATED

22”L (560MM) DEPTH, FOOT-TO-FOOT SPACE 32” (813MM) OVERALL 16”W (432MM) FOOT-TO-FOOT SPACE 25” (635MM) OVERALL 21”H (533MM)

DIMENSIONS CRATED

33”L (838MM) x 28”W (685MM) x 27”H (711MM)

Item Number: LIT-B300M/B350M/B350MV-354

MODEL 109PC ELECTRONIC HORIZONTAL SLICER W/ CONVEYOR

Shown: Md. 109PC Electronic Horizontal Slicer w/optional Take-away Conveyor

Slice whole muscle boneless product Accurately, Consistently, and Efficiently

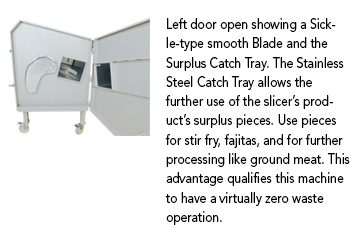

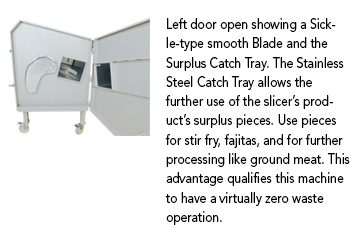

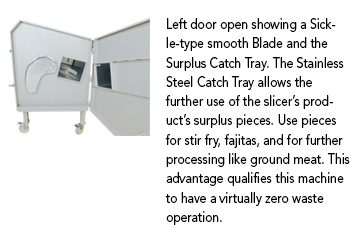

The Model 109PC Electronic Model can slice up to 180 slices per minute of Boneless Meat Products. This unit can raise your slicing operation to a Higher Level of Productivity to help Lower Labor Cost and Increase Profits. The specially designed sickle-type curved smooth blade slices the product cleanly (no tearing) thus increases product shelf life and reduces shrink and waste.

The 109PC Electronic model operates by a 7 Programmable Keypad that controls a microprocessor. The programmable keypad allows the operator to tailor the microprocessor to your product thickness from 1/16” (1.5mm) infinite thickness to 30” (762mm) max., reducing the time to change product thickness and operator training.

SPECIFICATIONS

MODEL

109PC Horizontal Slicer – Electronic

CONSTRUCTION

Stainless steel welded frame, panels, doors • Casters (plated body) with 5” (127mm) diameter Prevenz anti-microbial wheels • Stainless steel surplus tray.

MOTORS

Totally Enclosed Brake Motors:

| HP | KW | VTS/CY/PH | AMPS |

| 3 | 2.2 | 200-208-60-3 | 10.4-10.0 |

| 3 | 2.2 | 230/460-60-3 |

9.1-4.6 |

| 3 | 2.2 | 380-415-50-3 | 5.0-4.6 |

ELECTRICAL

Certified Electrician verify power line source voltage and ground for proper machine operation.

LOADING CHAMBER

9” (228mm)H x 10”(254mm)W x 30”(762mm)L, Textured finish Stainless Steel.

RECEIVING CHAMBER

9” (228mm)H x 10”(254mm)W x 35-1/2”(901mm)L, Textured finish Stainless Steel.

CONVEYORIZED EXIT CHAMBER

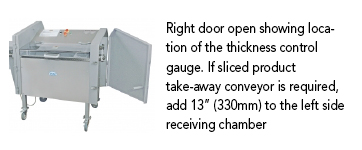

Add 13” (330mm) to left side of Exit Chamber (See picture and drawing).

PRODUCT TYPE

Input Chamber will accommodate a max. of 50 lbs. (22.6 kg) of Fresh or Frozen Tempered Boneless Meat Products or up to 30 lbs. (13.6 kg) max. of firm cheese product

CUTTING BLADES

Two special hardened Stainless Steel sickle style Blades are supplied with each machine. Select two blades – standard smooth edge or serrated edge Blades.

PRODUCT OUTPUT

Up to 180 slices p/min. at 1”(25.4mm) thick max.

SLICE THICKNESS

From 1/16” (1.5mm) infinite thickness to 30” (762mm) max.

SLICE CONTROLLER

Electronic • splash proof • User friendly Key Pad (English or Metric) (tactile and audible)• up to 7 Programable Programs • Auto transport return

SAFETY FEATURES

Magnetic Interlocks on all doors • Brake motors • Locking casters • OSHA Lockout Power Switch • Emergency “E” Stop Button

STANDARD ITEMS SUPPLIED

10’ (254mm) Size 12-4 wire Power Cord less plug • 2 pre-selected Cutting Blades – see above • Stainless Steel Surplus Catch Tray • Stainless Steel Product Guide Leaf Spring• Operating and Safety Manual

OPTIONS (EC)

9” (228mm) or 11” (279mm) Stainless Steel Leg Extensions • Stainless Steel Casters with 5” (127mm) diameter Prevenz Anti-microbial Wheels • a 10” (254mm)W x 48-3/8”(1219mm) L Product Take-away Conveyor, Variable Speed from 0 to 55 feet (0 to 16.8 meters) per minute – Removable Food Grade Belt – Independent On-Off Switch – Conveyor belt discharge height from floor is adjustable from 27” (686mm) to 31” (787mm). The min. and max. conveyor belt discharge height dimensions change accordingly when either 9” (228mm) or 11” (279mm) optional legs extensions are used.

CERTIFICATIONS

U.L., N.S.F., U.S.D.A.

WEIGHTS LESS CONVEYOR

Uncrated–660 lbs. (299kg)

Crated–1015 lbs. (460kg)

WEIGHTS W/CONVEYOR

Uncrated-795 lbs. (361kg)

Crated-1059 lbs. (480kg)

DIMENSIONS W/ OR W/OUT CONVEYOR (CONV. PACKAGED SEPARATELY)

Uncrated – 77”(1956”mm)L x 36-1/2 (927mm)H x 33-1/2 (851mm)W

Crated-85” (2159mm)L x 59” (1497mm)H x 40” (1016mm)W

Item Number: LIT-109PC-269

MODEL 109PC ELECTRONIC HORIZONTAL SLICER

Shown: Md. 109PC Electronic Horizontal Slicer w/optional Take-away Conveyor

Slice whole muscle boneless product Accurately, Consistently, and Efficiently The Model 109PC Electronic Model can slice up to 180 slices per minute of Boneless Meat Products. This unit can raise your slicing operation to a Higher Level of Productivity to help Lower Labor Cost and Increase Profits. The specially designed sickle-type curved smooth blade slices the product cleanly (no tearing) thus increases product shelf life and reduces shrink and waste.

The 109PC Electronic model operates by a 7 Programmable Keypad that controls a microprocessor. The programmable keypad allows the operator to tailor the microprocessor to your product thickness from 1/16” (1.5mm) infinite thickness to 30” (762mm) max., reducing the time to change product thickness and operator training.

SPECIFICATIONS

MODEL

109PC Horizontal Slicer – Electronic

CONSTRUCTION

Stainless steel welded frame, panels, doors • Casters (plated body) with 5” (127mm) diameter Prevenz anti-microbial wheels • Stainless steel surplus tray.

MOTORS

Totally Enclosed Brake Motors:

| HP | KW | VTS/CY/PH | AMPS |

| 3 | 2.2 | 200-208-60-3 | 10.4-10.0 |

| 3 | 2.2 | 230/460-60-3 |

9.1-4.6 |

| 3 | 2.2 | 380-415-50-3 | 5.0-4.6 |

ELECTRICAL

Certified Electrician verify power line source voltage and ground for proper machine operation.

LOADING CHAMBER

9” (228mm)H x 10”(254mm)W x 30”(762mm)L, Textured finish Stainless Steel.

RECEIVING CHAMBER

9” (228mm)H x 10”(254mm)W x 35-1/2”(901mm)L, Textured finish Stainless Steel.

CONVEYORIZED EXIT CHAMBER

Add 13” (330mm) to left side of Exit Chamber (See picture and drawing).

PRODUCT TYPE

Input Chamber will accommodate a max. of 50 lbs. (22.6 kg) of Fresh or Frozen Tempered Boneless Meat Products or up to 30 lbs. (13.6 kg) max. of firm cheese product

CUTTING BLADES

Two special hardened Stainless Steel sickle style Blades are supplied with each machine. Select two blades – standard smooth edge or serrated edge Blades.

PRODUCT OUTPUT

Up to 180 slices p/min. at 1”(25.4mm) thick max.

SLICE THICKNESS

From 1/16” (1.5mm) infinite thickness to 30” (762mm) max.

SLICE CONTROLLER

Electronic • splash proof • User friendly Key Pad (English or Metric) (tactile and audible)• up to 7 Programable Programs • Auto transport return

SAFETY FEATURES

Magnetic Interlocks on all doors • Brake motors • Locking casters • OSHA Lockout Power Switch • Emergency “E” Stop Button

STANDARD ITEMS SUPPLIED

10’ (254mm) Size 12-4 wire Power Cord less plug • 2 pre-selected Cutting Blades – see above • Stainless Steel Surplus Catch Tray • Stainless Steel Product Guide Leaf Spring• Operating and Safety Manual

OPTIONS (EC)

9” (228mm) or 11” (279mm) Stainless Steel Leg Extensions • Stainless Steel Casters with 5” (127mm) diameter Prevenz Anti-microbial Wheels • a 10” (254mm)W x 48-3/8”(1219mm) L Product Take-away Conveyor, Variable Speed from 0 to 55 feet (0 to 16.8 meters) per minute – Removable Food Grade Belt – Independent On-Off Switch – Conveyor belt discharge height from floor is adjustable from 27” (686mm) to 31” (787mm). The min. and max. conveyor belt discharge height dimensions change accordingly when either 9” (228mm) or 11” (279mm) optional legs extensions are used.

CERTIFICATIONS

U.L., N.S.F., U.S.D.A.

WEIGHTS LESS CONVEYOR

Uncrated–660 lbs. (299kg)

Crated–1015 lbs. (460kg)

WEIGHTS W/CONVEYOR

Uncrated-795 lbs. (361kg)

Crated-1059 lbs. (480kg)

DIMENSIONS W/ OR W/OUT CONVEYOR (CONV. PACKAGED SEPARATELY

Uncrated – 77”(1956”mm)L x 36-1/2 (927mm)H x 33-1/2 (851mm)W

Crated-85” (2159mm)L x 59” (1497mm)H x 40” (1016mm)W

Item Number: LIT-109PC-269

MODEL 109PCM MECHANICAL HORIZONTAL SLICER

The Model 109PCM Mechanical Model can slice up to 170 slices respectively per minute of Boneless Meat Products. This unit can raise your slicing operation to a Higher Level of Productivity to help Lower Labor Cost and Increase Profits. The specially designed sickle-type curved smooth blade slices the product cleanly (no tearing) thus increases product shelf life and reduces shrink and waste.

The 109PCM Mechanical model can slice up to 170 fresh Boneless Meat Products per minute. This Mechanical version operates via a preset Indexing Thickness screw type Mechanism that produces a same slice thickness the full length of the product. The machine can be stopped in process and a different slice thickness from 1/16” (1.5mm) up to 1-1/8” (28.6mm) thick max. can be selected and then finish cutting the product at that different thickness.

SPECIFICATIONS

MODEL

109PCM Horizontal Slicer – Mechanical

CONSTRUCTION

Stainless steel welded frame, panels, doors • Casters (plated body) with 5” (127mm) diameter Prevenz anti-microbial wheels • Stainless steel surplus tray.

MOTORS

Totally Enclosed Brake Motors

| HP | KW | VTS/CY/PH | AMPS |

| 2 | 1.5 | 208/230-60-3 | 7.0 |

| 2 | 1.5 | 460-60-3 |

3.2 |

| 2 | 1.5 | 200-60-3 | 7.3 |

| 2 | 1.5 | 380-415-50-3 | 3.5-3.3 |

ELECTRICAL

Certified Electrician verify power line source voltage and ground for proper machine operation.

LOADING CHAMBER

9” (228mm)H x 10”(254mm)W x 30”(762mm)L, Textured finish Stainless Steel.

RECEIVING CHAMBER

9” (228mm)H x 10”(254mm)W x 35-1/2”(901mm)L, Textured finish Stainless Steel.

CONVEYORIZED EXIT CHAMBER

Add 13” (330mm) to left side of Exit Chamber (See picture and drawing).

PRODUCT TYPE

Input Chamber will accommodate a max. of 50 lbs. (22.6 kg) of Fresh or Frozen Tempered Boneless Meat Products or up to 30 lbs. (13.6 kg) max. of firm cheese product.

CUTTING BLADES

Two special hardened Stainless Steel sickle style Blades are supplied with each machine. Select two blades – standard smooth edge or serrated edge Blades

PRODUCT OUTPUT

Up to 170 slices per minute.

SLICE THICKNESS

From 1/16” (1.5mm) up to 1-1/8” (28.6mm) thick max.

SLICE CONTROLLER

Main on/off Switch • Run or jog switch • Push button start switch

SAFETY FEATURES

Magnetic Interlocks on all doors • Brake motors • Locking casters • OSHA Lockout Power Switch • Emergency “E” Stop Button

STANDARD ITEMS SUPPLIED

10’ (254mm) Size 12-4 wire Power Cord less plug • 2 pre-selected Cutting Blades – see above • Stainless Steel Surplus Catch Tray • Stainless Steel Product Guide Leaf Spring• Operating and Safety Manual

OPTIONS (EC)

9” (228mm) or 11” (279mm) Stainless Steel Leg Extensions • Stainless Steel Casters with 5” (127mm) diameter Prevenz Anti-microbial Wheels • a 10” (254mm)W x 48-3/8”(1219mm) L Product Take-away Conveyor, Variable Speed from 0 to 55 feet (0 to 16.8 meters) per minute – Removable Food Grade Belt – Independent On-Off Switch – Conveyor belt discharge height from floor is adjustable from 27” (686mm) to 31” (787mm). The min. and max. conveyor belt discharge height dimensions change accordingly when either 9” (228mm) or 11” (279mm) optional legs extensions are used.

CERTIFICATIONS

Pending – N.S.F.

WEIGHTS LESS CONVEYOR

Uncrated-621 lbs. ( 282kg)

Crated-961 lbs. (436kg)

WEIGHTS W/CONVEYOR

Uncrated-756 lbs. (343kg)

Crated-1126 lbs. (511kg)

DIMENSIONS W/ OR W/OUT CONVEYOR (CONV. PACKAGED SEPARATELY)

Uncrated – 72-11/16”(1846.3mm)L x 35-3/16”(893.8mm)H x 33-1/2”(851mm)W

Crated – 85”(2159mm)L x 60”(1524mm)H x 40”(1016mm)W

Item Number: LIT-109PCM-334