| INDEX |

| SAWS (9) |

| GRINDERS (14) |

| SLICERS (7) |

| VACUUM TUMBLERS (7) |

| CUTTERS CHIPPERS, PRO SERIES, FOOD FORMERS |

Carl G. Biro, Sr. was an American immigrant who founded the seedling company of BIRO Manufacturing in the early 1920's. Carl had a humble beginning as the son of a local blacksmith in his native country of Hungary. After settling in America, Carl became an apprentice who attended technical school at night and on the weekends Eventually, Carl became the proprietor of his own meat market. During his proprietorship, he realized the need for a practical machine which would cut meat more effectively. Thus, in 1921, unable to ignore his ambitions of creating a practical meat cutter, Carl decided to dispose of his meat market so that he could devote more time to his concept. He leased an old church and used the equipment which was available and affordable at the time to pursue his "American Dream" and produce the first BIRO Power Meat, Fish and Bone Cutter. In time, Carl's machine gained national as well as international recognition and acceptance. Biro's leadership in the meat cutting industry was unmistakably established. In order to keep up with the growing product demand, BIRO Manufacturing moved from the leased church building to a small but modern factory building. This establishment has grown to be the facility which now houses our corporate headquarters |

Today, The BIRO Manufacturing Company markets over 35 items, including meat saws, tenderizers, meat grinders, chicken cutters, vacuum tumblers, horizontal slicers, and other meat processing machinery. This equipment is used in the United States and throughout the world. The company has certainly grown tremendously from the tiny seedling factory conceptualized by Carl Biro during the early 20's! Those involved in The BIRO Manufacturing Corporation today strive for progress towards a still more advanced product and to gain a greater measure of goodwill and respect from those who deal with it. We here at BIRO face the future with the firm belief that . .."The best is yet to come." |

Cutters, Chippers, Pro Series, Food Formers

MODEL BCC-100 POULTRY CUTTER

Knife guide trough not shown

Cut chicken, turkey, duck, fish, and rabbit all day with the BIRO BCC-100 Poultry Cutter. The special 9” cutting blade lets you cut pieces accurately while providing minimal tearing of the skin. You achieve almost no cutting loss and almost no product shrink. Since the blade is designed to slice instead of tear product tissue, your shelf life is maximized.

The 3/4 horsepower motor ensures that you have all of the power you need, and the machine design lets you cut for maximum productivity. The BCC-100 is designed for easy wash down and good sanitation. Left hand design machines are available if your product flow requires it.

SPECIFICATIONS

MODEL

BCC-100 POULTRY CUTTER.

CONSTRUCTION

STAINLESS STEEL BASE, COLUMN,

EXTENSION SHAFT.

MOTORS

| MOTORS | VOLTS | CYCLE | PH | AMPS | CODE |

| 3/4 HP (.5 kw)-TE |

115/230 | 60 | 1 | 10.8/5.4 | STD |

| 3/4 HP (.5 kw)-TE |

115/230 | 50 |

1 | 12.0/6.0 | EC |

| 3/4 HP (.5 kw)-TE |

208-230/460 | 60 | 3 | 2.9-2.7/1.4 | EC |

| 3/4 HP (.5 kw)-TE |

190/380 | 50 | 3 | 3/1.5 | EC |

STD=STANDARD EC=EXTRA COST

STANDARD FEATURES

5’ CORD AND 3 PRONG PLUG ON 115 VOLT, 5’ CORD NO PLUG ON 208-230/460 VOLT, KNIFE GUIDE TROUGH, OPERATING AND SAFETY MANUAL.

SWITCH

TILT TYPE, ENCLOSED, WATERPROOF.

INTERLOCK SWITCH

MICRO TYPE, ENCLOSED, WATERPROOF.

KNIFE BLADE

STAINLESS STEEL, 9” (228 MM) DIAMETER, DOUBLE BEVEL.

CUTTING GUIDE BAR

APEX TYPE, STAINLESS STEEL 1” (25 MM) DIAMETER.

KNIFE GUIDE TROUGH

STAINLESS STEEL, STANDARD.

OPTIONS (EC)

LEFT HAND UNIT (BLADE ON LEFT SIDE OF MOTOR), SERRATED KNIFE BLADE (IN PLACE OF STANDARD KNIFE BLADE), CALIFORNIA STATE REQUIREMENT

COUNTER SPACE REQUIRED

18” (457 MM) L X 18-1/2” (470 MM) W X 22” (560 MM) H.

CERTIFICATION

U.S.D.A.

WEIGHT

UNCRATED: 75 LBS. (35.4 KG) APPROXIMATE.

CRATED: 83 LBS. (37.7 KG) APPROXIMATE.

DIMENSIONS CRATED

L = 20” (508 MM) W = 23” (584 MM) H = 21” (533 MM).

Item Number: LIT-BCC-100-086

MODEL FBC-4800SS TEMPERED FROZEN BLOCK CHIPPER

- A 60 lb. tempered, frozen meat block can be chipped in less than 60 seconds.

- Save approximately

2-1/2 lbs. of meat from

each chipped meat block.

No sawdust generated.

- Bloom qualities are uniform and excellent.

- No measurable chipper product loss.

- Better utilization of other cutting machinery

for retail processing.

- Better utilization of man power for other

productive duties.

- Reduce saw blade usage.

- Extra handling of meat sticks is eliminated.

- Planned productivity is assured.

- Quality control is maintained.

- Minimum product shrinkage occurs.

- Minimum operational heat is generated.

- Better bloom.

- Extends case life.

SPECIFICATIONS

FBC-4800SS TEMPERED FROZEN BLOCK CHIPPER

CONSTRUCTION

STAINLESS STEEL CONSTRUCTION

MOTORS

| HP | KW | TYPE | VOLTS | AMPS | CYCLE | PH | STATUS |

| 5 | 3.75 | OP | 208-230/460 | 16-15/7.5 | 60 | 3 | STD |

| 5 | 3.75 | OP | 220/380-415 | 15/8.7-7.9 |

50 | 3 | STD |

| 5 | 3.75 | OP | 575 | 6 | 60 | 3 | EC |

OP= OPEN STD=STANDARD EC=EXTRA COST

SWITCH

MAGNETIC TYPE WITH LOW VOLTAGE AND OVERLOAD PROTECTION.

TRANSMISSION

OIL BATH WITH HEAVY DUTY BRONZE GEAR FITTED DIRECTLY TO MOTOR.

STANDARD EQUIPMENT

POLYETHYLENE PRODUCT RECEPTACLE, PRODUCT RECEPTACLE DOLLY, TWO FLOOR BOLT DOWN LOCATOR CHOCKS, OPERATING AND SAFETY MANUAL.

OPERATION

MAXIMUM BLOCK SIZE 8” (203 MM) X 16-1/2” (419 MM) X 19-1/2” (495 MM). RECOMMENDED BLOCK TEMPERATURE 15° F TO 25° F (-10° C TO -4° C) CAN REDUCE BLOCK INTO CHIPS APPROXIMATE 3-1/2” (89 MM) X 3-1/2” (89 MM) X 1/4” (6.4 MM) IN LESS THAN 60 SECONDS.

CLEANING

LID OPENS FOR EASY ACCESS, ENTIRE KNIFE SHUTTLE ASSEMBLY REMOVABLE AS A UNIT FOR CLEANING.

OPTIONS (EC)

STAINLESS STEEL DISCHARGE CHUTES, LONGER AND WIDER LEGS FOR PRODUCT DISCHARGE INTO CONVEYOR. CALL FACTORY

CERTIFICATIONS

N.S.F., U.L., C.S.A., U.S.D.A.

WEIGHT

UNCRATED: 533 LBS. APPROXIMATE

CRATED: 610 LBS. (277 KG) APPROXIMATE

DIMENSIONS CRATED

L = 54” (137 CM), W = 45” (114 CM), H = 38” (96.5 CM) (LEGS ARE FOLDED UP FOR SHIPPING)

Item Number: LIT-FBC-137

PRO-9 SERIES

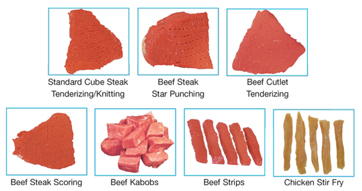

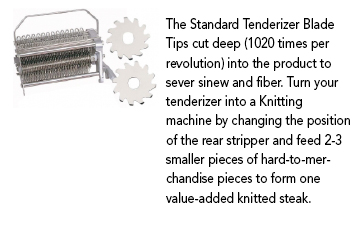

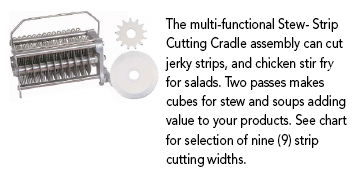

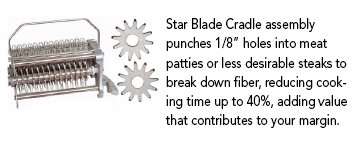

The PRO-9 Series machines are merchandising centers and offer great versatility. Use the Standard Tenderizer Cradle assembly to tenderize and knit beef products. The Strip Cutting assembly for strip cutting of beef and chicken stir-fry products, or for fajitas and julienne for salads, beef jerky strips, and beef cubing for kabobs and stews. The Star Roller assembly can punch 1/8” lasting holes in beef patties to make the beef more tender and reduce cooking time up to 40%.

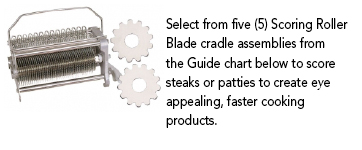

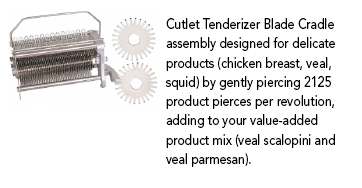

Use multiple surface Scoring Rollers to enhance eye-appealing beef patties. Use the specially designed Cutlet Tenderizer Roller assembly to enhance the texture and tenderness of veal, chicken breasts, veal parmesan, veal scalopini, or squid by gently piercing the product without tearing. The PRO-9 Series machines help merchandise product by adding value to less expensive, less desirable, and less tender products, thereby enhancing your profit margin.

SPECIFICATIONS

SPECIFICATIONS BY MODEL

CONSTRUCTION

STAINLESS STEEL BASE, ALUMINUM HEAD STANDARD, STAINLESS STEEL HEAD STRUCTURE EC.

| MODEL | Pro-9SD 1/2HP | Pro-9HD 1/2HP | Pro-9HD 3/4HP |

| Electrical Supply | 5′ (1524mm) 3 wire power cord • on 115V, 3 prong ground plug • on 220V – less plug |

| Construction | Stainless steel case, case top • lexan transparent safety feed cover • coated steel frame |

| Safety Switch | Motor shuts down when safety feed cover is raised |

| Transmission Drive | Poly flex double v-bel |

| Transmission: Alum., Oil bath |

Bronze sleeve bearings • fiber drive gear | Ball bearings • steel gears |

| Roller Speeds | 105 R.P.M. Std. | 115 R.P.M. Standard 140 R.P.M. Optional – No Cost |

| Certifications | N.S.F. • U.S.D.A. • U.L. • C.S.A. • C.F.I.A. |

| Standard Features | TA3130 Dual purpose tenderizing/knitting assembly • operating and safety manual |

| Options: | Heavy duty rigid S.S. combs • stainless steel safety cover • cradle storage box |

| Weights: Approximate – depending on options |

| unpacked | 69 lbs. (31 kg) | 70 lbs. (32 kg) | 73 lbs. (33.1 kg) |

| packed | 74 lbs. (33.6 kg) | 75 lbs. (34 kg) | 78 lbs. (35 kg) |

| Dimensions packed | L=20” (508mm) x W=20” (508mm) x H=19” (483mm) |

MOTORS

STANDARD & OPTIONAL

| HP | KW | TYPE | VOLTS | AMPS | CYCLE | PH | STATUS |

| 1/2 SD | .38 | TEFC DP | 115/230 | 6.6/3.3 | 60 | 1 | STD |

| 1/2 HD | .38 | TEFC DP | 115/230 | 6.6/3.3 |

60 | 1 | STD |

| 3/4 HD | .56 | TEFC DP | 115/230 | 8.4/4.2 | 60 | 1 | STD |

| 1/2 SD | .38 | TEFC DP | 115/230 | 8.4/4.2 | 50 | 1 | EC |

| 1/2 HD | .38 | TEFC DP | 115/230 | 8.4/4.2 |

50 | 1 | EC |

| 3/4 HD | .56 | TEFC DP | 115/230 | 13.6/6.8 | 50 | 1 | EC |

SD=STANDARD DUTY HD=HEAVY DUTY STD=STANDARD TEFC DP=TOTALLY ENCLOSED FAN COOLED, DRIP PROOF

Standard and Optional Cutting Cradle Assemblies

| ITEM NO. | DESCRIPTION Dimensions in inches/mm | COVER TYPE | PRO-9SD 1/2HP | PRO-9HD 1/2HP | PRO-9HD 3/4HP |

| TA3130 | Std. (tenderizing) cradle asm. | L | STD | STD | STD |

| TA3130-50 | Cutlet (tenderizing) cradle asm. | SS |

EC | EC | EC |

| TA3130-9A | 1/4”/6.3 Stew-strip cradle asm. | L | NA | EC | EC |

| TA3130-5A | 3/8”/9.5 Stew-strip cradle | L | NA | EC | EC |

| TA3130-4A | 9/16”/14.3 Stew-strip cradle | L | NA | EC | EC |

| TA3130-1A | 3/4”/19.1 Stew-strip cradle | L |

EC | EC | EC |

| TA3130-14A | 7/8”/22.2 Stew-strip cradle | L | EC | EC | EC |

| TA3130-2A | 1”/25.4 Stew-strip cradle | L | EC | EC | EC |

| TA3130-3A | 1-1/4”/31.7 Stew-strip cradle | L | EC | EC | EC |

| TA3130-7A | 1-9/16”/39.7 Stew-strip cradle | L |

EC | EC | EC |

| TA3130-8A | 2”/50.8 Stew-strip cradle | L | EC | EC | EC |

| TA3130-36 | Star blade roller cradle | L | EC | EC | EC |

| TA3130-20 | Scoring cradle, 0” roller gap | L | NA | EC | EC |

| TA3130-21 | Scoring cradle, 1/16”/1.6 roller gap | L |

NA | EC | EC |

| TA3130-22 | Scoring cradle, 1/8”/3.2 roller gap | L | EC | EC | EC |

| TA3130-23 | Scoring cradle, 3/16”/4.8 roller gap | L | EC | EC | EC |

| TA3130-24 | Scoring cradle, 1/4”/6.4 roller gap | L | EC | EC | EC |

STD=Standard L=Lexan EC=Extra Cost NA=Not Available SS=Stainless Steel

______________________________

______________________________

______________________________

______________________________

______________________________

______________________________

______________________________

______________________________

______________________________

______________________________

Scoring Cradle Blade Assemblies

| Product Type | Patty Thickness | Front Blade Dia. | Back Blade Dia. | “A” Gap Dimensions |

| Recommended Blade Roller Assembly combination for 1/16” Depth of scoring on each side of patty (dimensions in inches/mm) |

| Soft | 1/8”-1/4”/3.2-6.4 | 2”/50.8 | 2”/50.8 | 0 |

| Soft | 1/4”-1/2”/6.4-12.7 | 2”/50.8 |

1-7/8”/47.6 | 1/16”/1.6 |

| Frozen | 1/4”/6.3 | 1-7/8”/47.6 | 1-7/8”/47.6 | 1/8”/3.2 |

| Frozen | 5/16”/7.9 | 1-7/8”/47.6 | 1-3/4”/44.5 | 3/16”/4.3 |

| Frozen | 3/8”/9.5 | 1-3/4”/44.5 | 1-3/4”/44.5 | 1/4”/6.3 |

Note:If deeper scoring is desired, use the larger dia. blade roller combination than recommended

Item Number: LIT-PRO9-131

MODELS F2000N/F3000N/

F4000N/HD3000EHN FOOD/PATTY FORMING MACHINES W/ CONVEYOR

B1200N BISCUIT/COOKIE FORMER

Shown: Optional- Detachable Product Feed Tray with Model HD3000EHN EH = Extended Hopper

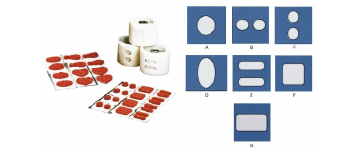

The BIRO F2000N/F3000N/F4000N/HD3000EHN/B1200NFood/Patty Forming Machines are designed for production of a wide variety of meat and food products, with maximum production output capability from 2000 to 4000 formed products per hour. A large number of drum mold die shapes are available to select from. From the standard round shapes of different widths, to square, oval, rectangle, fish, cutlet, heart, chicken leg, chicken nuggets, ear, rabbit, bone, tree, pork chop, etc. See illustrations to the right.

The key feature of this machine is the design of the Mold (die) in the drum. The operator can select infinite product weights by changing the drum die depth (thickness) up to 3/4” (19mm). You do not need different die cups and plates each time you want to change weights. The Food Former Models are compact, have a small foot print, easy to clean-up, and are reliable and versatile. A real Value-Added Profit Center all its own.

SPECIFICATIONS

MODELS

| F2000N F2000- EHN |

F3000N F3000- EHN |

F4000N F4000- EHN |

B1200N | HD3000- EHN |

| Product Type |

Protein | Biscuits | Protein |

| Motor: 3/4HP (.56Kw) 115V, 60 Cy, 1 Ph.– 7.9A, IP55, 220V, 60 Cy, 1 Ph.- 4.0A, IP55 |

Standard | 115V or 220V, 50 or 60 Cy., 1 Ph. wired to a 3 Ph. Inverter for Variable Speed (drum/ conveyor synchronized). Must specify Voltage and Cy. |

Standard |

| Motor: 3/4HP (.56Kw), 220V, 50 Cy, 1 Ph.- 4.4A, IP55 |

Optinal –o No Cost | Optional – No Cost | |

| Mold Drum – one Single Hole Mold Drum supplied with machine. see Mold Shape Selection Chart |

White Poly – select one, any standard shape, Single Hole Drum at No up-charge | Alum. Drum – Double Round Holes, 50mm ea. No upcharge | White Poly – select one, any shape, Single Hole Drum at No up-charge |

| 2 or more Mold Drums |

Optional – Extra Cost – Advise Shape or Shapes required |

| Auto Paper Feed 5-1/2”x 5-1/2” (139mm x 139mm) sq.> |

Standard Equipment | Optional – Extra Cost | Standard Equipment |

| Foot Switch – stops former and conveyor | Standard Equipment |

| Product Hopper 6.5 Gal. – 25 L. (30 lbs.) |

Std. Equipment on F2000N, F3000N, F4000N, B1200N only | N/A |

| S.S. Feed Tray, detachable, 60 lb. (27.2kg) capacity |

Optional – Extra cost on F2000N, F3000N, F4000N, B1200N only | N/A |

| Extended Product Hopper – 10.5 Gal. – 40 L. (60 lbs.) | Standard Equipment on all EHN’s only | N/A | Standard Equipment |

| Manual Wire Cleaner |

Standard Equipment | N/A |

| Pneumatic Wire Cleaner -65 PSI air min. required |

Optional – Extra Cost | Standard Equipment |

| Std. Conveyor Belt, 15-3/8” (390.5mm) long | Standard Equipment | N/A |

| Longer Conveyor Belt, 35-3/8” (898.5mm) long | Optional – Extra Cost | N/A |

| Extra Long Conveyor Belt, 45” (1180mm) long, included on frame with casters | N/A | Standard Equipment |

| Wire mesh conveyor belt 15-3/8” (390.5mm) long – not NSF Certified * | Optional – Extra Cost | N/A |

| Wire Mesh conveyor belt 35-3/8” (898.5mm) long – not NSF Certified * | Optional – Extra Cost | N/A |

| Larger stainless steel feed paddles when making 120mm x 20 to 25mm thick, and for 130mm patty any thickness | Optional – Extra Cost |

| Patty paper – size 5-1/2” (139mm) square – heavy wt. strength, 20,000/ case min. |

Optional – Extra Cost | Not Applicable | Optional – Extra Cost |

| Variable Speed – Drum & Conveyor Synchronized | N/A | Standard Equipment | N/A |

| Cleaning Tilt Stand | Standard Equipment | N/A |

| N.S.F., E.T.L. Certification | Yes * | No |

F=Former; N=NSF; B=Biscuit; EH=Extended Hopper; HD=Heavy Duty; 2000, 3000, 4000, 1200 = cycles per hour; Protein = red meat, pork, chicken, etc.; Biscuits = cookies, biscuits; N/A = Not Avail;. S.S. = Stainless Steel

DIMENSIONS & WEIGHT

| MODELS | F2000N | F3000N | F4000N | B1200N |

| Dims. (Std. Conv.) | L24” (610mm) x W23” (584mm) x H28” (711mm) |

| W/Long Conv. | L43” (1092mm) x W23” (584mm) x H28” (711mm) |

| Weight | 147 lbs (66.6kg) | 164 lbs (74.4kg) | 148 lbs (67.1kg) |

| Shipping Weight | 191 lbs (86.5kg) | 208 lbs (94.5kg) | 193 lbs (87.6kg) |

| Crate Dims. | L27” (690mm) x W30” (760mm) x H31”(780mm) |

| MODELS | F2000EHN | F3000EHN | F4000EHN | HD3000EHN |

| Dims. (Std. Conv.) | L24” (610mm) x W23” (584mm) x H35” (889mm) | L59” (1499mm) x W29” (730mm) x H58.5” (1481mm) |

| W/Long Conv. | L43” (1092mm) x W23” (584mm) x H35” (889mm) |

| Weight | 152 lbs (68.9kg) | 169 lbs (76.7kg) | 225 lbs. (102 kg) |

| Shipping Weight | 197 lbs (89.4kg) | 214 lbs (97.2kg) | 436 lbs (198 kg) |

| Shipping Weight | L27” (690mm) x W30” (760mm) x H39”(990mm) | L54” (1371mm) x W45” (1143mm) x H63” (1600mm) |

DRUM MOLDS - MOST POPULAR

| Round Single Hole (A) | Oval Single Hole (D) |

| F9320000-63.5 | 63.5mm | F9320000-1-6550 | 60mm x 50mm |

| F9320000-70 | 70mm | F9320000-1-10070 | 100mm x 70mm |

| F9320000-76.2 | 76.2mm | F9320000-1-11070 | 110mm x 70mm |

| F9320000-80 | 80mm | F9320000-1-11090 | 110mm x 90mm |

| F9320000-85 | 85mm | F9320000-1-12070 | 120mm x 70mm |

| F9320000-90 | 90mm | F9320000-1-12080 | 120mm x 80mm |

| F9320000-100 | 100mm | |

| F9320000-101.6 | 101.6mm | Double Rectangular Hole (E) |

| F9320000-104 | 104mm | F9320002-2-8020 | 80mm x 20mm |

| F9320000-105 | 105mm | F9320002-2-9023 | 90mm x 23mm |

| F9320000-110 | 110mm | F9320002-2-9030 | 90mm x 30mm |

| F9320000-115 | 115mm | F9320002-2-12025.4 | 120mm x 25.4mm |

| F9320000-120 | 120mm | |

| F9320000-127 | 127mm | Square Single Hole (F) |

| F9320000-130 | 130mm | F9320000-3-8080 | 80mm x 80mm |

| F9320000-3-9090 | 90mm x 90mm | |

| Round Double Hole (B) | F9320000-3-100100 | 100mm x 100mm |

| F9320002-8-30 | 30mm | |

| F9320002-8-40 | 40mm | Rectangle Single Hole (G) |

| F9320002-8-50/td> | 50mm | F9320000-7-9080 | 90mm x 80mm |

| F9320000-7-10070 | 100mm x 70mm | |

| Biscuit (Cookie) Forming (C) | F9320000-7-10080 | 100mm x 80mm |

| F9320004-50 | 50mm double, alum. | F9320000-7-13070 | 130mm x 70mm |

| Ask about other Shapes not shown. |

Item Number: LIT-FOODFORMERS-357